Ionic liquid (AMINOION®)Development of AMINOION®, a proprietary design that leverages our technology and know-how.

Our strength is that it can produce and handle a variety of products such as surfactants, glycol ethers and amines. By capitalizing on this strength as far as possible, we have developed AMINOION®, halogen-free ionic liquid that is a proprietary design that applies our production technology.

AMINOION® can be used as an anti-static agent, anti-fogging agent, ultra-hydrophilizing agent, wetting agent or stain-proofing agent.

As we have many types of AMINOION®, please feel free to contact us for more information.

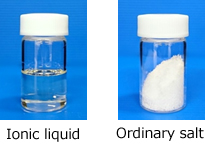

What is ionic liquid?

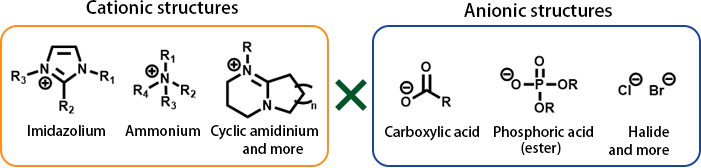

Ionic liquid is a “salt” that is liquid at room temperature. A salt that is composed of ions has been thought to be solid at room temperature due to its high melting point like sodium chloride. However, ionic liquid, which is liquid at or below 100°C due to its low melting point, is a unique substance with properties that have never been seen in other known liquids. In recent years, applied research on various applications of ionic liquid has been under way because of its properties and the high designability of structures formed of a combination of anions and cations.

AMINOION® Outline

| Product Name | AMINOION® |

|---|---|

| General Name | Ionic liquid |

1. Anti-fogging and anti-static agents

Characteristics

- The addition of a small amount of these agents to various kinds of polymers provide anti-static properties.

- As they do not excessively bleed out, they have superior water resistance (Table 1).

- Good antistatic performance is obtained at low humidifies.

- They can be used for such applications as paints, coating materials and films.

Water resistance evaluation (Table 1)

Units:Ω/□

| Polymer | Acrylate | Acrylic styrene | Polyester |

|---|---|---|---|

| No. of cleaning cycles | 0 times 5 times | 0 times 5 times | 0 times 5 times |

| AMINOION® Type 1 | 109 109 | 109 109 | 109 109 |

| Cationic surfactant* | 107 Over | 108 Over | 108 Over |

*Lauryltrimethylammonium chloride, 2% addition to polymer

- Water resistance evaluation method

One cycle consists of scrubbing with a sponge dampened with neutral detergent and rinsing with water.

After drying, surface resistivity is measured.

- Surface resistivity

Mitsubishi Chemical Hiresta UP: URS probe

Measurement at an applied voltage of 250V, 25℃ and 50%RH

Blank:over 1013

In addition to anti-static properties, we offer a lineup of various types of AMINOION® to address various applications.

- AMINOION® with superior heat resistance which can be applied to polymer compounds.

- AMINOION® with hydrophilic, anti-fogging properties.

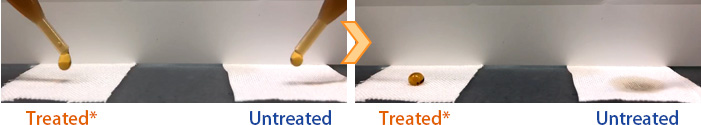

2. Fluorine-free water repellent agents for textiles

Characteristics

- The AMINOION® SC Series modifies textile surfaces to provide excellent water repellency.

- Fluorine-free water repellent agents compliant with the PFAS restriction proposal.

- The agents are immobilized on fibers through a coupling reaction, thus achieving excellent durability.

- It is also possible to provide anti-static properties at the same time due to the presence of ionizable groups in the molecular structure.

- Water repellency appears at lower temperatures than with conventional water-repellent finishes, promising saved energy and reduced environmental impact.

*100% cotton (bleached No. 20 count cotton yarn) cloth impregnated with a 10% aqueous solution of AMINOION® Type 2, and dried at 110°C for 30 minutes

Evaluation example: Evaluation of water repellency and anti-static properties

| Treatment agent | None | Si coupling agent (water-repellent type) |

AMINOION® Type 2 |

AMINOION® Type 3 |

|---|---|---|---|---|

| Treatment temperature (°C)*¹ |

– | 160 | 110 | 110 |

| Water contact angle (°) | 0 (absorbing water) | 139 | 146 | 135 |

| Surface resistivity (Ω/□) | 1010 | >1014 | 108 | 1010 |

① Fabric (100% cotton, bleached No. 20 count yarn) impregnated with a 10% solution of treatment agent

② Dried for 30 minutes in a thermostatic chamber

(*¹ Minimum treatment temperature for water repellency to take effect)

Water contact angle: 30 seconds after placing the drop, at 25°C

Surface resistivity: Mitsubishi Chemical Hiresta UP; measurement with URS probe under conditions of applied voltage 10–25 V, 25°C, and 50% RH

The AMINOION® Series proved to provide excellent water repellency and anti-static properties at the same time, as well as allowing for lower treatment temperatures. The performance in the evaluation example (water repellency and anti-static properties) also provides excellent resistance to washing.

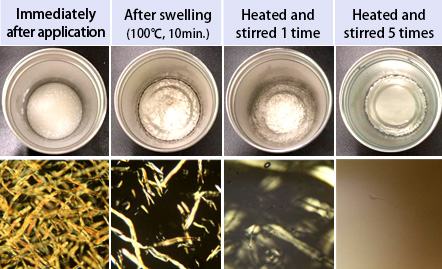

3. Cellulose-dissolving agents

Characteristics

- Can dissolve cellulose, allowing for utilization of unused biomass such as wood and agricultural waste.

- Enables extraction of high-molecular-weight cellulose, which holds promise for application as a substitute for petroleum-derived plastics.

- Ionic liquid can be recycled for use.

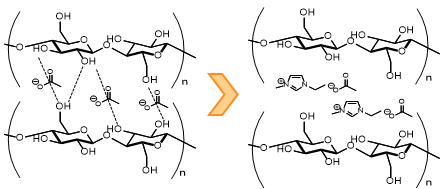

Cellulose dissolution process and mechanism

Insertion of anionic species between the strong hydrogen bonds in cellulose enables dissolution without lowered molecular weight.

Shows promise for various applications.

Ionic liquid design

Design of customized structures is also available upon request.